Ballard Inspired Wall Plaque Tutorial

12 October 2011

Hey! I am flying home from a family vacation today.

So, I am skipping the recipe party today!! Sorry!

Please come back next week, I will have everything up and running!

Ballard Inspired Wall Plaque Tutorial

So, I am skipping the recipe party today!! Sorry!

Please come back next week, I will have everything up and running!

Ballard Inspired Wall Plaque Tutorial

I guest posted on Craftiness is not Optional with this tutorial a few weeks ago as part of Jess'sThe Sincerest Form of Flattery series co-hosted by kojo designs...

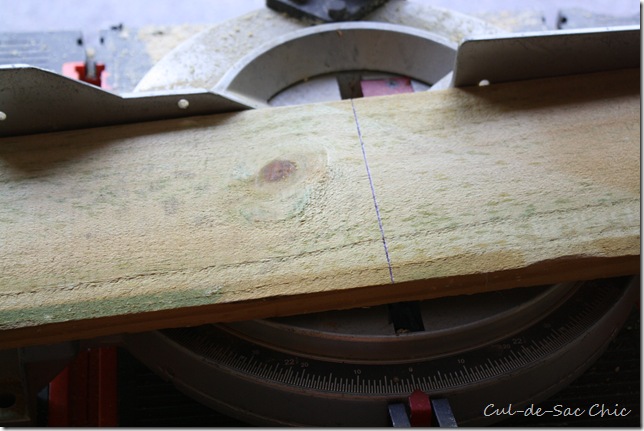

The knock off I am sharing today is a woodworking project. I don't actually make many knock off projects. Here's what always happens to me... I see something at a store or in a catalog and think "I could make that", but then I never follow through or I figure out it would have been cheaper to just buy it. My knock off today, however, is a different story. I had the motivation (Jess asked me to guest post :) and I managed to knock off a $259 item for about $75. Ready to see it?

Here is the Ballard Designs Pruvost Wall Plaque...

|

| image source |